Your web browser is out of date. Update your browser for more security, speed and the best experience on this site.

Turbo Compressors LPT 150

With the greatest efficiency for low pressures

With the new LPT 150 low pressure turbo compressor, there is significant progress in the low pressure range: while the operating costs decrease, low-maintenance and wear-free turbo technology supplies stable, absolutely oil-free compressed air between 2 and 4 barpsi.

It is not just the small footprint that makes a big impression

BOGE LPT 150

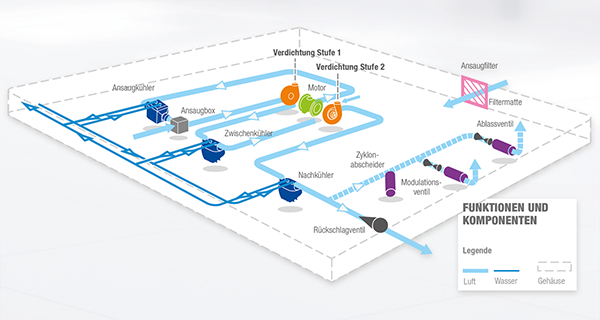

Function / Components

The titanium impeller

The new benchmark for oil-free compressed air

High level of efficiency and low costs

- Oil- free class 0:

no oil in the machine, no oil in the air - Concentrating on what is important:

each component optimised for its operational purpose - Ideal for low pressures:

permanent magnet motors with high energy density ensure first-class efficiency - Optimal degree of efficiency:

excellent specification thanks to turbo technology - Low maintenance requirement:

no gears, no oil and considerably fewer bearings - Unbelievably low overall costs:

up to 30% lower than oil-free screw compressors

- Barely perceptible:

only around 63 dB(A) compared to about 80 dB(A) for an oil-free screw compressor - BOGE quality, made in Germany:

uniquely high vertical integration

Ideal solution for the low pressure range

Anywhere where low pressures between 2 and 4 barpsi are what are required, the new LPT 150 low pressure turbo technology from BOGE expands the scope straight away.

Water and waste water treatment

The LPT 150 is not only of interest to municipal water suppliers. Many large production facilities maintain their own systems for treating waste water by bubbling compressed air at low pressure.

Metal processing / assembly lines

Whether it is cooling using compressed air, or discharging shavings from motor blocks and gearboxes – the LPT 150 is ideally suited to the low pressures required in the metal processing industry.

Glass manufacturing and other special fields

Completely oil-free operation is an important criterion in the plastic, chemical and food industries, in paint shops and in glass manufacturing (archive image) – besides the gain in efficiency in the low pressure field.

BOGE Kontakt

Do you have any further questions?

We will be pleased to explain the specific advantages of this innovative technology to you. Please do not hesitate to contact us.